Head office

Via Martiri della liberazione, 12, 23875, Osnago, (LC), Italia

Website

about us

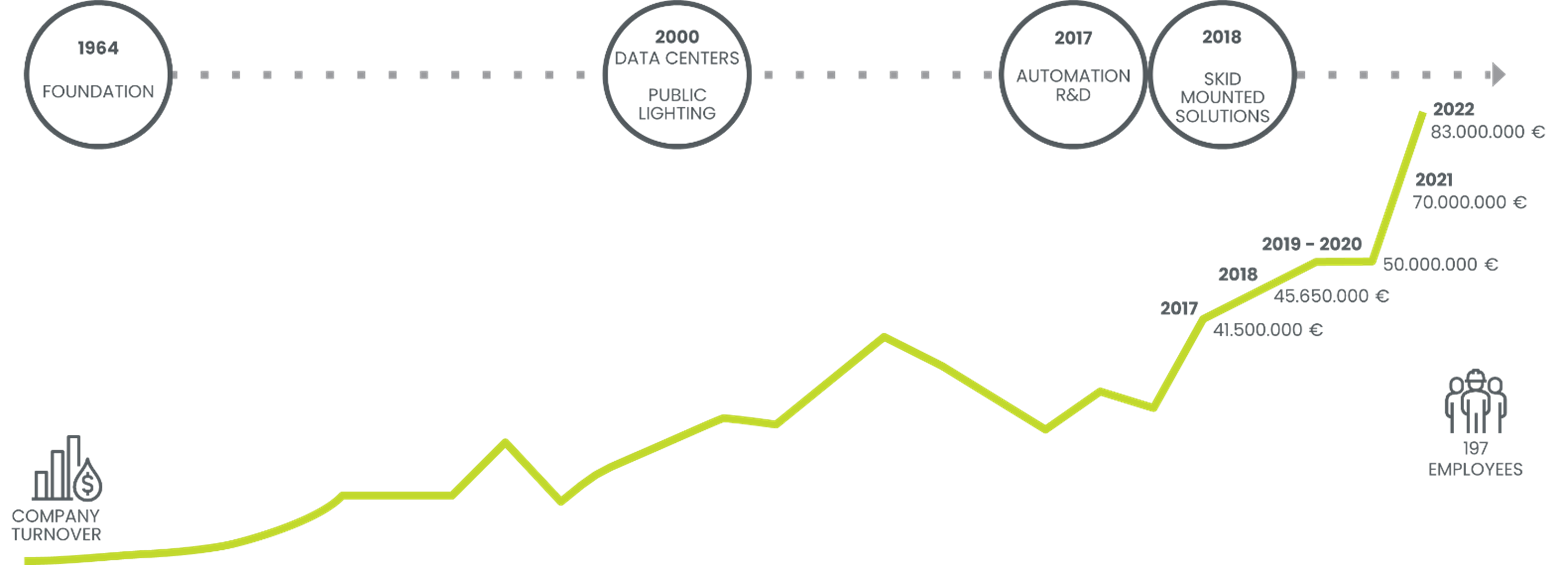

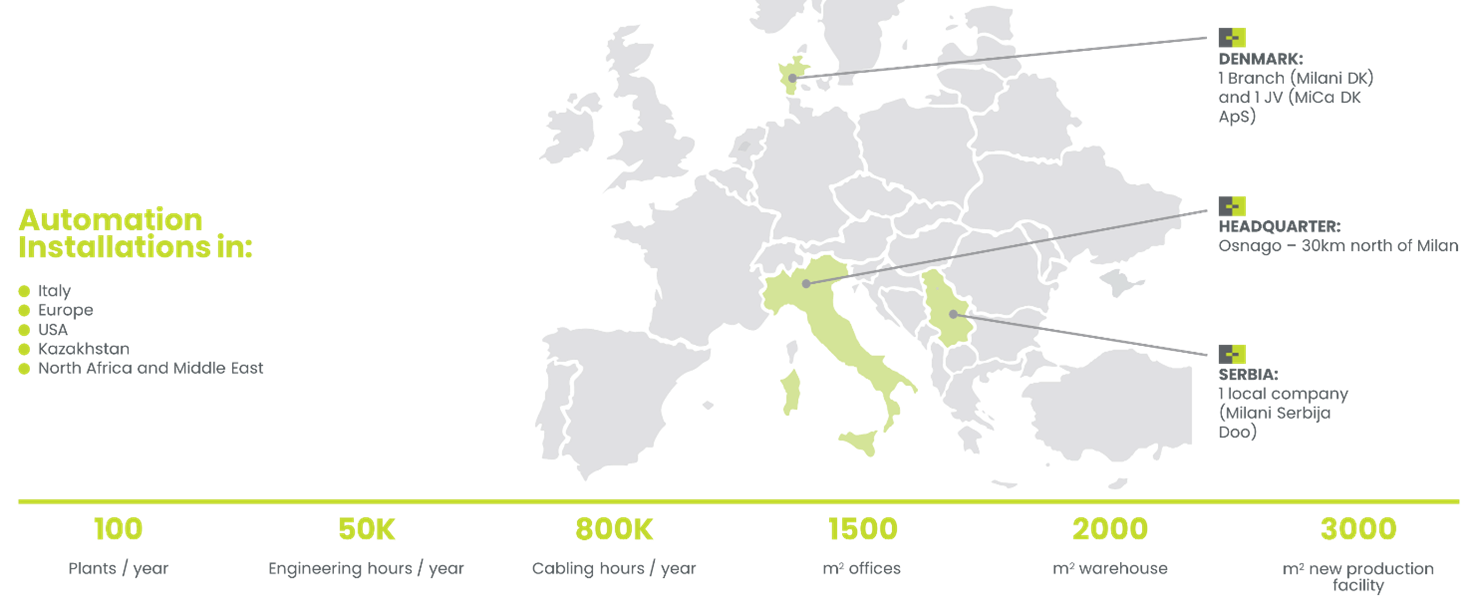

Milani S.p.A., founded in 1964 in Osnago (LC), specializes in the development of MEP systems and turnkey technological solutions. The company has become one of the leading international players in the industry, expanding into Europe with branches in Denmark and Serbia. The quality of its supplies is supported by certifications in terms of quality, safety, and environmental management.

Over the last 15 years, the company has developed a growth strategy based on increasing its internal skills; first by bringing in-house certifications and skills for the creation of structured cabling, creating an internal engineering team with high skills in the BIM field, then creating an internal automation and Research and Development group made up of 25 senior engineers and technicians with many years of experience in the sector, dedicated to the creation and implementation of integrated hardware-software solutions for:

- BMS for Automation, supervision and management of buildings (official partner Siemens Desigo, Johnson Control, Schneider Electric, Beckhoff, Copadata)

- Industrial automation with capabilities in:

- Process automation (PLC+HMI, SCADA, DCS)

- Hazardous area control panel design

- SIL3 certified applications

- I&A engineering, including Hazop and SIL analysis

- Energy Storage and integrated applications for the advanced tertiary sector (IoT)

In 2018, with the integration of the business unit M2C Industrial, thanks to the wide experience of its staff (more than 20 years in oil&gas and gas treatment industry), Milani has enlarged its core business to the engineering and construction of:

- Dosing and Injection skid mounted units

- Gas and fluid filtration, purification and pressure regulation

- H2 generation, treatment and storage

- BOP skid mounted or containerized units

With references worldwide, our production cycles are managed fully internally in our facilities in Italy located just 20 minutes north of Milan (with only the exception of galvanization or special paintings for which we have consolidated suppliers) and particular care is paid to the test of the units before shipment, in order to provide to our clients a very high-quality level.

Thanks to the important development of core competences and the creation of innovative projects that have combined concepts related to the IoT (Internet of Things) and energy monitoring and saving for the creation of Smart Plants, in the last year we have filed a patent application and obtained recognition as Siemens AG's best European partner of the year 2020 for building automation and recognition awarding the Technology Beauty Contest of Confindustria Lombardia as best product automation in 2021.

The R&D team of Milani S.p.A. has developed in partnership with important international companies a concept to provide Green H2 technology, with important applications in several industries. One of the most interesting and growing applications is related to the railways back-up of equipment geographically spread throughout the territory, like rail-crossing, signals, traffic lights, etc. Norwegian and Baltic railways have already started an investment program in these solutions, to decarbonize and solve logistic issues related to operation and maintenance of the traditional solutions.

This solution, in fact, can offer meaningful operation advantages comparing to the traditional solutions, in terms of:

- Highest energy density carriage (33kWh/kg vs Diesel: 11.97 kWh/kg)

- Reduced maintenance on equipment (just one control of 4-6h once per year)

- Highest reliability on the market (for this it is used in aerospace industry)

- Safer than normal fuels (gasoline / diesel)

- Fully Green (with 0 CO2 emissions, 0 NOx Emissions, 0 SOx emissions)

- Not noisy (<60dB(A) @ 1meter)

- If produced locally, no need to have logistics OPEX for refueling.

Milani has been investing a lot in the development of hydrogen integrated systems in the last year, having internally all the competences needed for the provision of an integrated package:

- Nearly 20 years of experience in large PV installation on the ground and on roofs, with plenty of references all around Italy

- Internal staff coming from Siad Macchine Impianti group, with more than 25 years of experience in dealing with H2 plants

- Having invested in R&D activities to develop H2 generation, distribution and energy reconversion plants, with 1 pilot under finalization at our facility and 2 executive projects ongoing.

- Having internally plenty of references in automation systems for PMS and process management.

- Taking advantage of our internal competences in realizing containerized and skid-mounted high-quality prefabricated unit suitable to be installed in remote and environmental heavy areas, with a particular focus to the ergonomics of the operations.

PRODUCTS:

The products offered by MILANI SpA are as follows:

- Generation plants

- Purification

- Storage

- Hydrogen Compression

- Fuel Cell

Offer

- Products

Patents

- 2 brevetti per sistemi di indoor positioning (per controllo accessi, indoor navigation e asset tracking), utlizzati anche per la gestione delle attività di manutenzione:

- visualizzazione su PAD operatore dello stato delle utenze (variabili di stato, valori analogici, allarmi, documenti a supporto) o avvicinandosi all’item da manutenere o tramite riconoscimento immagini e visualizzazione delle informazioni in realtà aumentata.

Italiano

Italiano